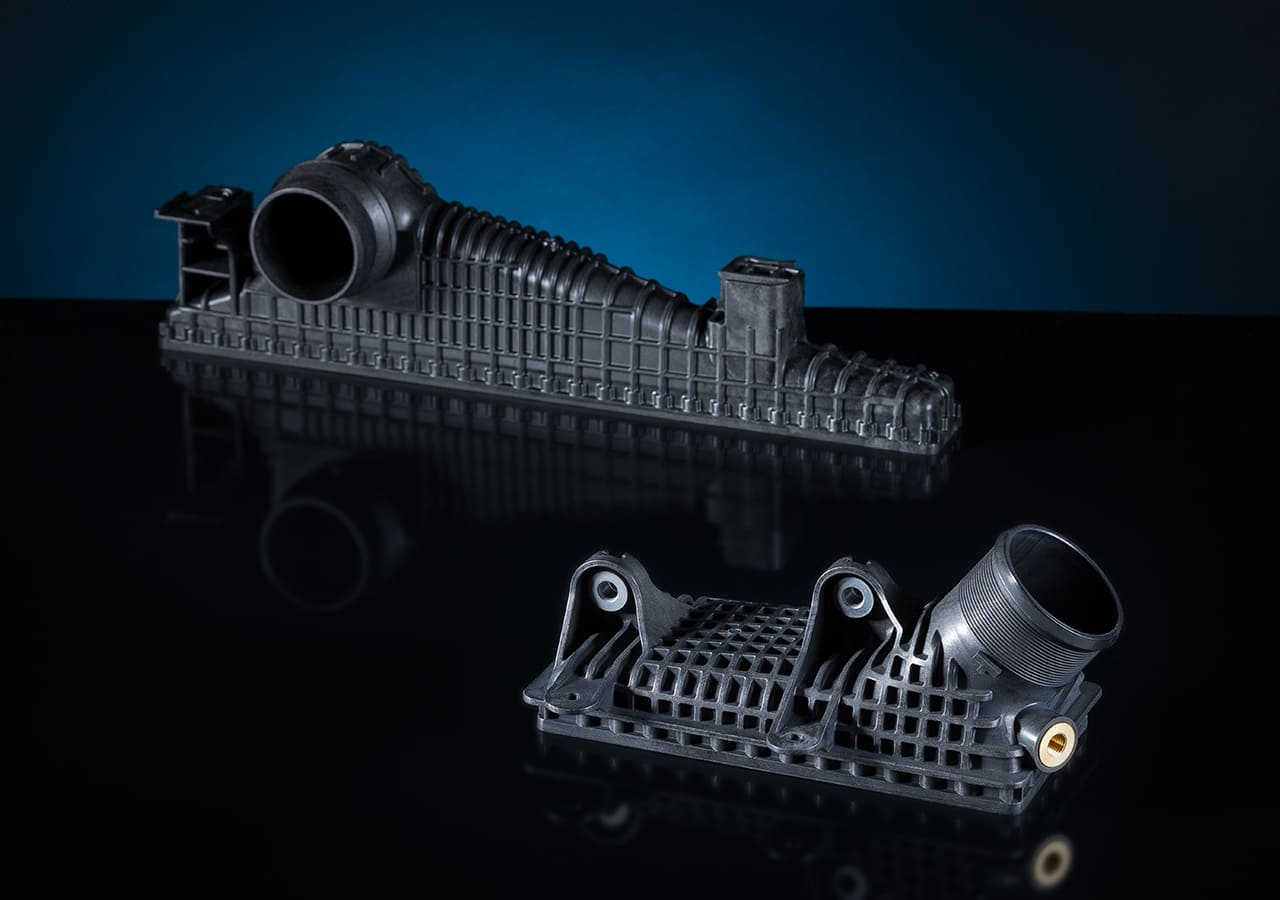

Components for engine cooling

We develop, produce and test cooling tanks

Our cooling tanks as a component of the engine cooler are made of glass fibre reinforced and hydrolysis resistant plastics. The component is provided with a seal and fastened to the radiator by means of flanging.

In addition to the demanding flatness tolerances and sealing requirements, the high glass fibre filling content of up to 50% poses an enormous challenge to injection moulds and processes, which we have mastered confidently thanks to our many years of expertise.

Downstream assembly and testing processes are part of our standard.

"While our customers determine the component quality, we put it into practice.

We comprehend, control and optimize processes which is why we are able to bring to series production each quality requirement of any product in a timely manner."