We purposefully take injection-molded components and system components for vehicles to series production.

Our expertise

High performance thanks to short development times, global manufacturing strategies and an outstanding series-production quality.

As a global and certified system partner we have been developing, producing and assembling plastic-based components and systems for renowned OEMs and manufacturers in the Automotive and Commercial Vehicle Industry for more than 40 years. We place project teams all over the world, in-house tool making and state-of-the-art injection molding technology. We focus our expertise already when developing and validating components and bundle all process steps at production sites close to our customers, which is why we are able to shorten development times, consistently reduce logistics costs and fully meet your aesthetic and functional requirements.

- Conveniently positioned with global project teams, in-house toolmaking and 22 companies around the world

- More than 40 years of experience in the production of plastic components for vehicles

- 100 % tested and fully automated state-of-the-art production and assembly technologies

- All conventional Automotive certifications and quality rules according to IATF 16949, TISAX® result available

- Just-in-time logistics solutions

Technology

Our full service to meet maximum demands on design, weight and stability.

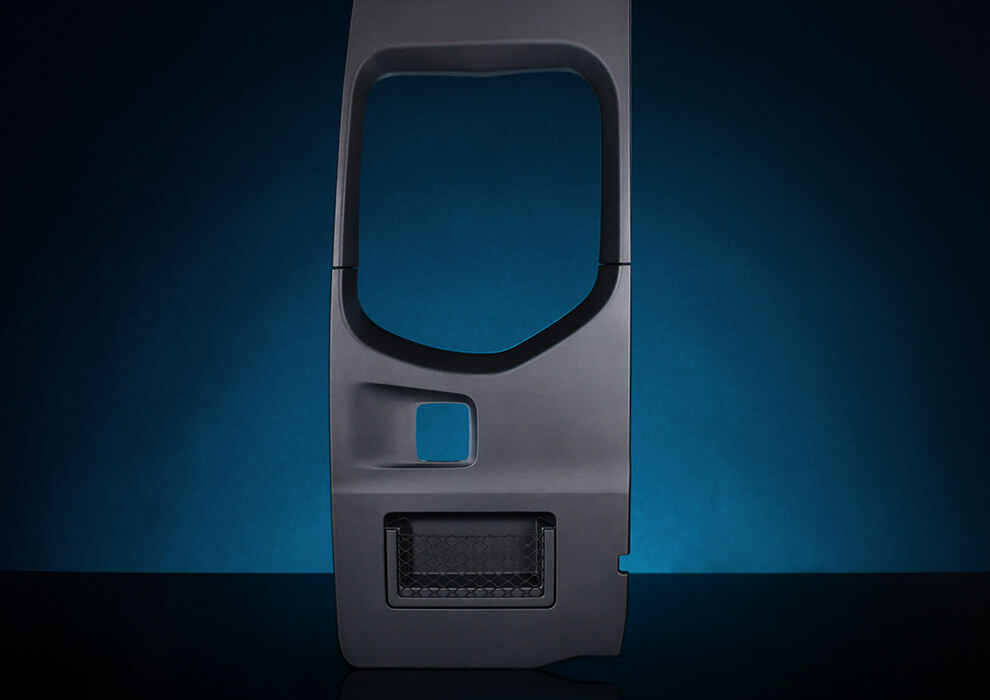

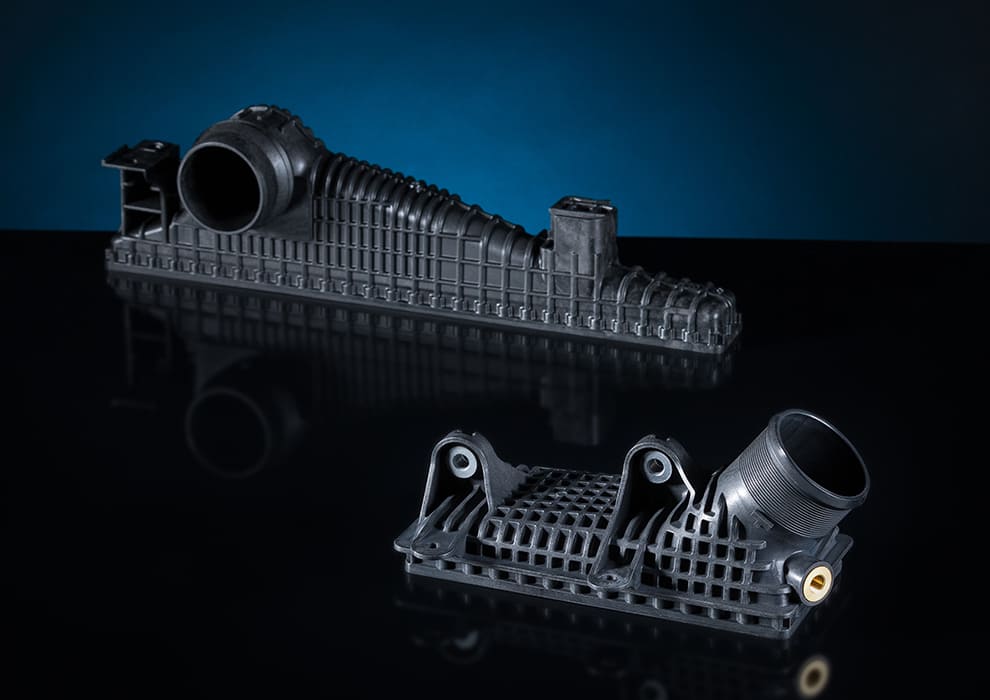

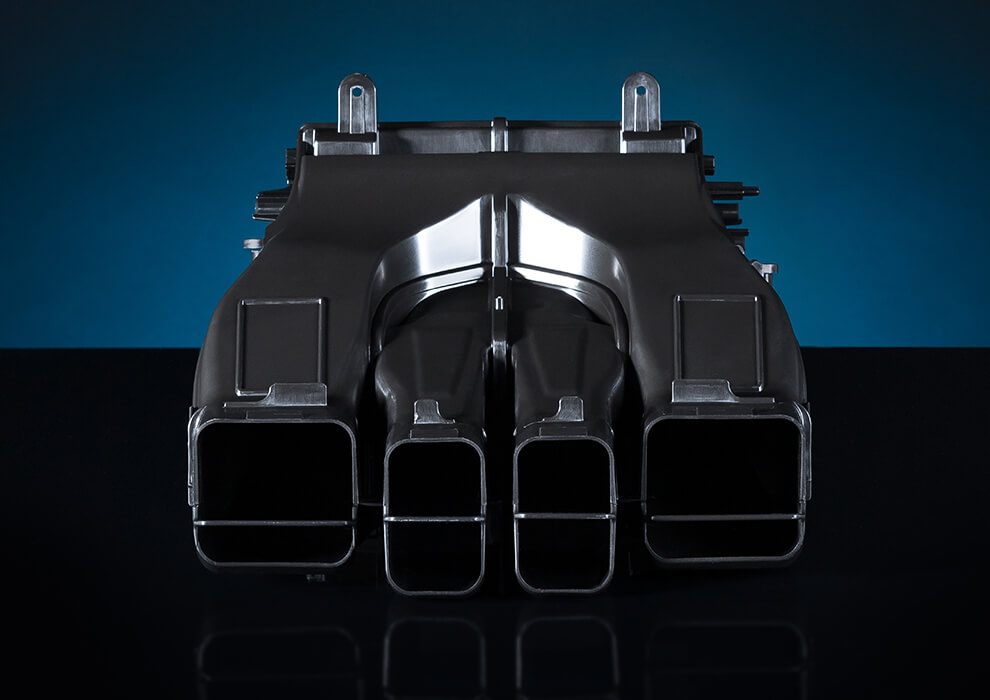

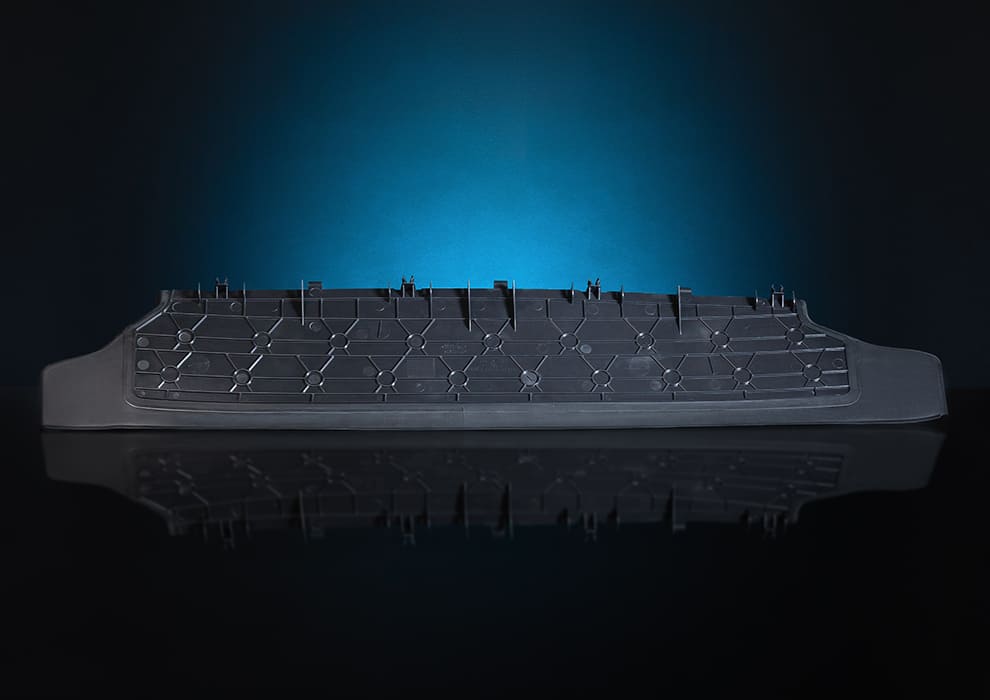

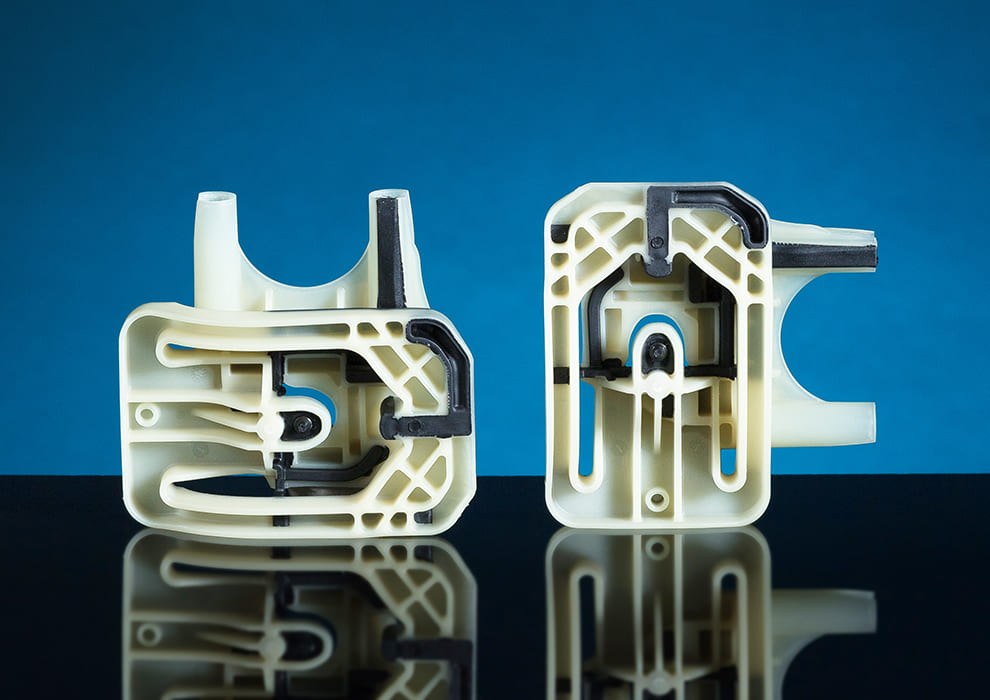

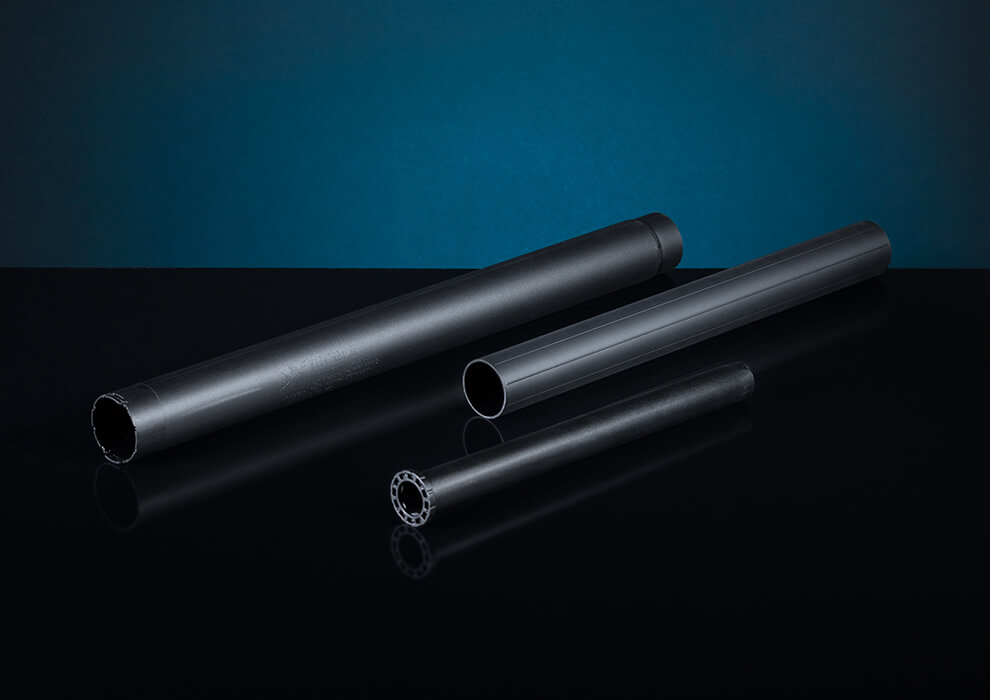

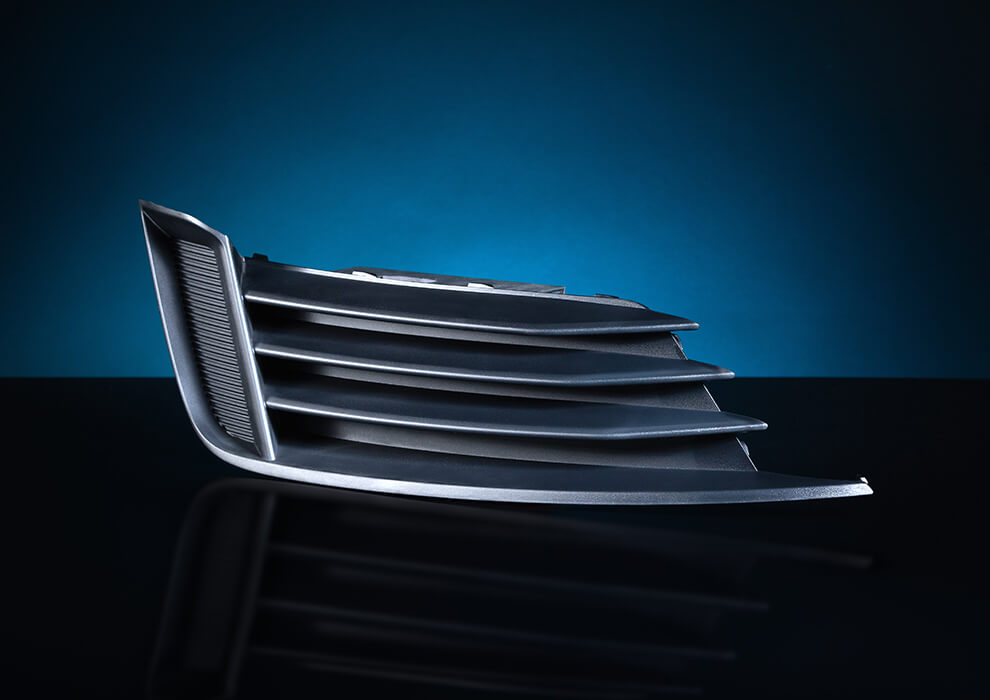

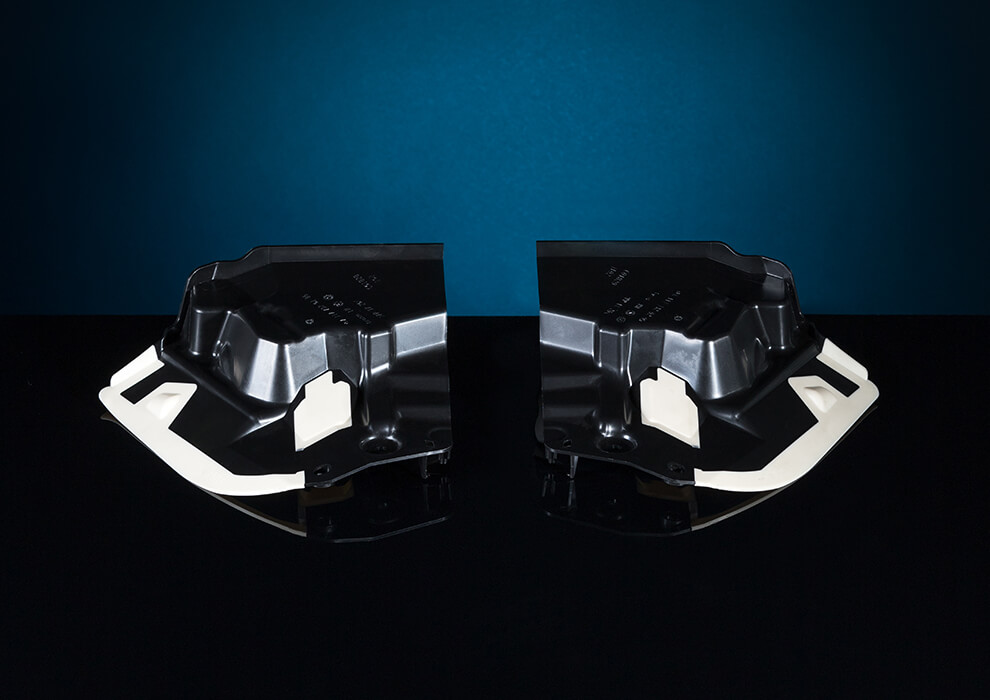

As a system supplier we are experts in physical foaming, a highly important technology for weight reduction, all conventional injection molding procedures and the full range of processing services, from functional integration, linked module assemblies up to component finishing and varnishing. We have developed an outstanding position in the market, particularly as regards large technical components with high quality requirements.

- Space-optimized part design and simulation

- In-house toolmaking, including large, complex components

- State-of-the-art injection molding procedure and finishing service

- Interlinked and automated series-production assemblies

- Glass fiber reinforced plastics, such as PA6 GF50, PP long glass fiber

Solutions

Reference projects of the Mobility market segment.

Our fans, shrouds, module carriers and net wind deflectors set standards around the world. This is one of the many reasons why leading manufacturers as well as tier 1 and 2 suppliers rely on the Wirthwein brand quality. We ask you for your understanding that we have to keep some projects back from you due to nondisclosure agreements.

Quality assurance

One reproducible, process-reliable series-production quality worldwide.

Incorporating our certified quality management system according to ISO 9001 and the provisions of IATF 16949, as well as your project-related specifications we assure the required quality along the whole value stream by utilizing controlled and fully automatic processes which we put into practice at each and every Wirthwein location. From our decades of experience we know what can be produced, where strengths are needed or how we can reduce weight by means of high-strength plastics and the right procedure.

Development, mold design and validation of parts

Component simulation, strength calculations, filling studies and FMEA.

Series production control

Optical and tactile measurements in in-house measuring rooms.

Annual requalification

Regular inspection of serial parts, supplier audits and repeat audits.

Our team

Wherever mobility development takes us, we will always respond to our customers‘ requirements.

Mario Bresink

Director Sales Mobility

Oliver Weiss

Global Key Account Manager

Mariusz Kucharski

Director Sales Central-Eastern Europe

Yannick Spiller

Global Key Account Manager

Harald Gerstl

Director Sales and PM Spain

Your project with Wirthwein

Get in touch with our Mobility team.

You have an inquiry, require technical advice or would like us to call you back? Then please make use of our contact form, write us an e-mail or just call us.

Phone

+49 7933 702 0

E-Mail

mobility@wirthwein.de